In the domain of contemporary manufacturing, particularly in the sectors of health and hygiene, the need for high-quality nonwoven fabrics has never been greater. Whether to create medical masks, air filters, or single-use gowns, the right machinery is a must. This is when the advanced meltblown and pp spunbond noodle equipment come on the stage.

Why Nonwoven Fabrics Are Important in Today’s Industry

Nonwoven fabrics are the fabric of life in innumerable industries. They possess a set of qualities that include home healthcare and industrial activities, their versatility, durability, and air filtration ability. The secret of manufacturing the exceptional quality of such fabrics is in the use of specialized fabric machines.

The COVID-19 pandemic crisis has seen a surge in demand for masks and healthcare products, since people were not used to wearing them. This situation has undoubted the necessity of the use of reliable and scalable production techniques available through machines such as the melt blown fabric machine and pp spunbond nonwoven fabric machinery.

What is Meltblown Fabric and Why is it Important?

Meltblown fabric is a type of nonwoven material created by blowing high-speed hot air onto a molten polymer. This process produces ultra-fine fibers that are excellent at filtering out particles. As a result, meltblown fabrics are a core material in the production of face masks, especially N95 respirators.

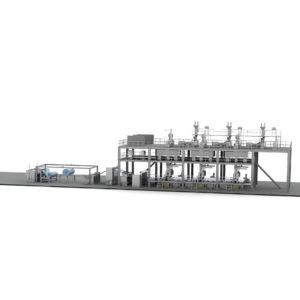

A high-quality meltblown machinery setup ensures consistent fiber diameter, uniform web formation, and high filtration efficiency. The precision and automation built into these machines also help minimize waste and ensure top-tier product quality. If you’re interested in upgrading or starting your own production line, you can explore a wide range of meltblown machinery that meets industrial standards and offers dependable performance.

What is Spunbond Fabric?

Spunbond is another widely used nonwoven fabric. It is produced by extruding thermoplastic polymers into continuous filaments that are then laid into a web and bonded. Compared to meltblown fabric, spunbond materials are stronger and more durable. They serve as the outer layers in surgical masks, protective clothing, and other medical-grade textiles.

Machines for producing pp spunbond nonwoven fabric are designed for high-speed, continuous operation. The pp spunbond nonwoven fabric machinery available today often includes advanced features like real-time monitoring, automatic control systems, and easy material changeover, making them ideal for businesses seeking efficient production at scale.

Combining Spunbond and Meltblown for Maximum Protection

In mask production, especially for high-protection equipment, a combination of spunbond and meltblown fabric is used. Known as SMS (Spunbond-Meltblown-Spunbond), this structure provides durability, breathability, and filtration all in one. Producing these composite fabrics requires having access to both melt blown fabric machines and pp spunbond nonwoven fabric machinery. Manufacturers who offer both types of machinery under one roof provide a significant advantage to customers looking for complete solutions.

For instance, the melt blown fabric machine is optimized to work alongside spunbond systems, helping companies create high-quality, multilayered fabrics used in everything from medical masks to industrial air filters.

What to Look for in Fabric Machinery

If you’re considering investing in meltblown or spunbond machinery, here are a few factors to keep in mind:

- Production speed: Higher throughput machines will improve productivity.

- Consistency: Uniform fiber distribution ensures quality performance.

- Automation and control: Advanced control systems minimize human error.

- Energy efficiency: Look for equipment designed to reduce power consumption.

- After-sales support: Access to parts, service, and training matters long term.

You can explore highly specialized equipment tailored for different production needs at GL Nonwoven Machinery. Their collection includes cutting-edge solutions for meltblown machinery, pp spunbond nonwoven fabric production, and more.

Future of Fabric Manufacturing

As technology evolves, the efficiency and capabilities of fabric machines continue to improve. Smart manufacturing, AI-assisted monitoring, and automation will become increasingly common in nonwoven production lines. By investing in high-quality meltblown machinery or a melt blown fabric machine, manufacturers position themselves at the forefront of this rapidly growing industry.

Final Thoughts

When it comes to producing critical materials like masks, filters, and medical textiles, equipment makes all the difference. With the right combination of meltblown machinery and pp spunbond nonwoven fabric machines, businesses can achieve consistent quality, better output, and increased reliability. Whether you’re upgrading your current line or starting a new venture, choosing the right fabric machine is a decision that pays long-term dividends.