পণ্যের বর্ণনা

1.Company Profile:

2.Product details

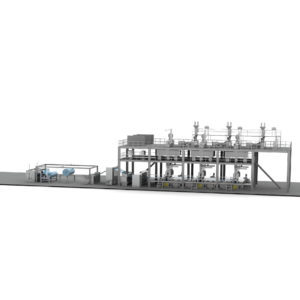

2-1:Main Technology data

1.Fabric width:1600mm(Availed width)

2.Maximum winding diameter:Φ2000MM

3.Capacity:According70 g/㎡,20t/24h

4.Monofilament size:<2.5d

5.Fabric weight:10~150g/㎡

6.Designed speed:350M/MIN ;(Working speed:300 M/MIN)

7.Product quality standard: According to the samples confirmed by both parties, according to the data confirmed by both parties.

2-2. product description

1. SS Nonwoven Machine Adopts an intelligent electrical control cabinet and spinning drafting system. সিস্টেম কন্ট্রোলিং মোড উন্নত এসি ফ্রিকোয়েন্সি-মডুলেটেড গতিতে বৈশিষ্ট্যযুক্ত, সম্পূর্ণ ডিজিটাল সিঙ্ক্রোনাইজড যোগাযোগ.

2. SS Nonwoven Machine is double-beam, owns obvious higher quality as well as obvious larger quantity in production than S Nonwoven Machine.

And SS Nonwoven Machine runs in high efficiency and low power consumption. Based on the features above, SS Nonwoven Machine can help customers to save labor and wide compatibility with different high requirements of productions.

3. SS Nonwoven Machine is the professional manufacturer in double layers non-woven fabric.

4. About the package: we pack the main machine parts in wooden cases; the electrical parts will be packed with plastic and then packed into wooden cases; With the steel structure, they will be packed into containers.

2-3 Technical Parameter

3.Main parts

1.Maximum working pressure: 16MPa

2.Maximum working temperature: 310℃

3.Single cylinder filter area: 0.5-19㎡

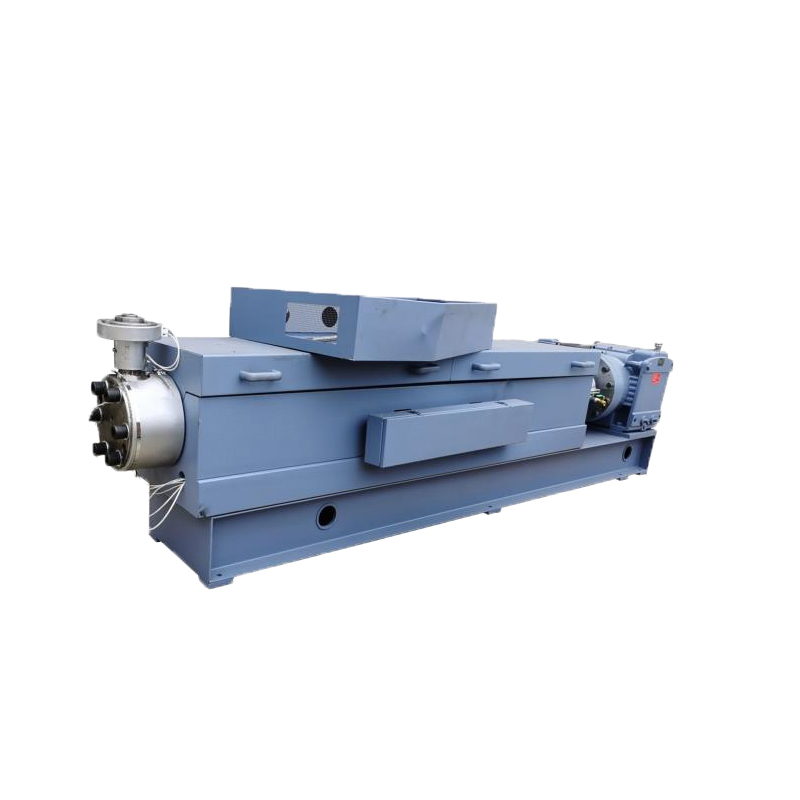

1. Aspect ratio L/D=30:1.

2.Screw diameter: Φ150mm

3.Siemens Bede AC motor 110kw, Fuji frequency controller

4.The spiral cylinder and screw are made of high-strength nitriding steel, equipped with resistance heater, divided into several heating zones, including a full set of electrical control devices, including power, temperature control, pressure control, ইত্যাদি. see the plasticizing capacity of electric control part for details

1. Cold water circulation system, cooling water pipeline and water tower

2. The head of the cryocompressor is made in Hanzhong, Taiwan,চীন,150T/H;

3.The water supply system is made of glass fiber, and the designed daily water consumption is about 1 cubic meter (mainly for cooling water supplement)

1.The high temperature calcined spinneret is used to melt a large amount of polymer on the parts and then flow into the collection container at the lower part of the furnace

2. Automatic integration, with low vacuum alarm, over temperature alarm, water cut-off alarm and other advanced safety protection devices

4.application

5.Packing & Shipping

6.FAQ

1. Q:How long will your engineer reach our factory?

A:Within one week after everything ready (machine arrival your factory, non woven material,

power source, air compressor etc.Prepared)

2. Q:Does your engineer understand English?

A:Our engineers understand a little English. All our engineers have more than five years machine

installation experience.

3. Q:What should we charge for your engineer?

A:You should charge for the cost of our engineer’s air tickets, hotel, food, and also their salary

800CNY one day per person.

4. Q:How many days it will take for the intallation?

A: It will take around 45 days, depends on the machine type.

5. Q:How do we solve the machine problem after your engineer leaving?

A:Generally speaking, there will be no problem after finishing installation. In case you have any

problem, you can contact our sales at any time. Our engineers will take a solution video according

your description.

7.our service

Pre-Sales One-stop Service

After-Sales Service

* Inquiry and consulting support

*One year warranty

* Lastest industry trends

* Machine test video before delivery

* More fit bag making solution

English Manual. Electric Diagram

* Sample testing support

* Training how to instal the machine, training how to use

* view our Factory

the machine

Suggest layout support

*Engineers available to service machinery overseas