Descripción del Producto

1.Company Profile:

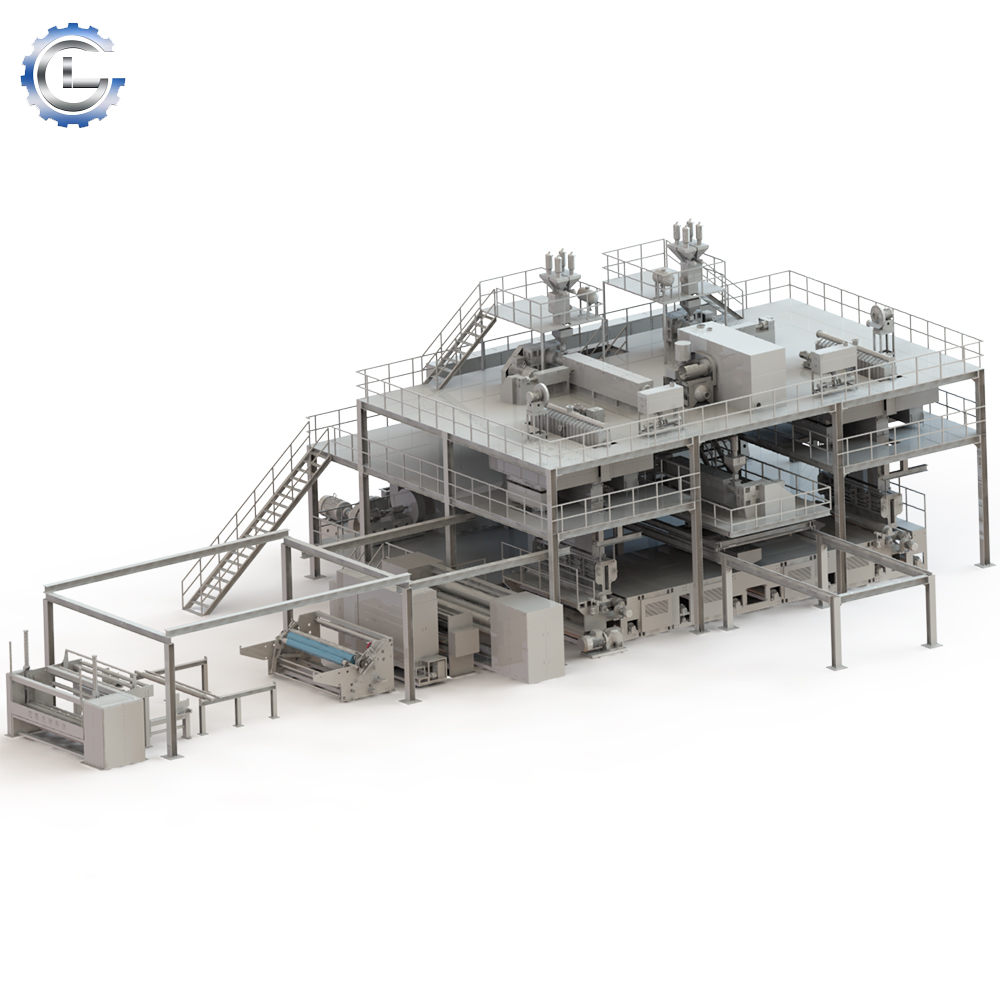

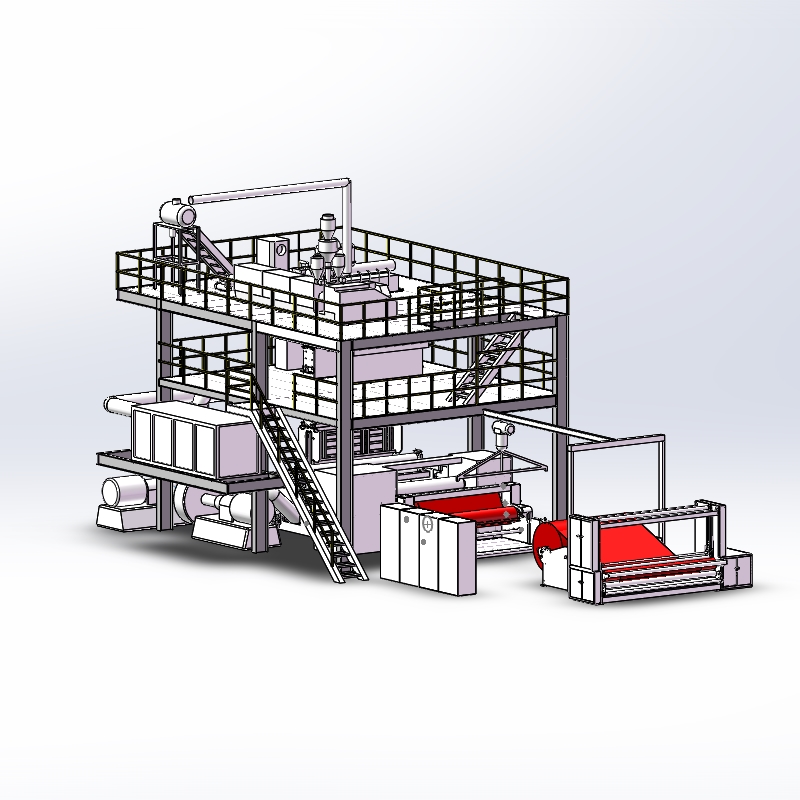

2.Product details

2-1:Main Technology data

1.Fabric width:1600mm(Availed width)

2.Maximum winding diameter:Φ1500MM

3.Capacidad:According70 g/㎡,9-10t/24h

4.Monofilament size:<2.5d

5.Fabric weight:10~200 g/㎡

6.Designed speed:150M/MIN ;(Working speed:130 M/MIN)

7.Tamaño del equipo:length 15 *width10* height 11

The following word will introduce the features of S Spunbond Nonwoven Machine:

1. S Spunbond Nonwoven Machine adopts an intelligent electrical control cabinet and spinning drafting system. El modo de control del sistema presenta una velocidad avanzada de frecuencia modulada de CA., comunicaciones sincronizadas totalmente digitales.

2. S Spunbond Nonwoven Machine is featured by lower investment, compact construction, small covering area, and labor-saving.

3. S Spunbond Nonwoven Machine is a single-beam professional manufacturer of single-layer nonwoven fabric equipment which is manufactured for PP/PET/PLA/Bi-Component Spunbond nonwoven fabrics’ producción. Después de la entrada de materias primas., undergo the process of extrusion, hilado, quenching, closure air stretching, web formation, calendaring, winding and cutting as per requirements and then packed for storage and delivery.

4. As the fabrics have great intensity, buena transpirabilidad, and good feeling, they are widely used for various fields such as home decoration, furniture covers, clothing shoe leather, industrial and agricultural protective covers, medical and sanitary supplies, beauty products and so on.

2-3 Technical Parameter

3.Main parts

1.Maximum working pressure: 16MPa

2.Maximum working temperature: 310℃

3.Single cylinder filter area: 0.5-19㎡

1. Aspect ratio L/D=30:1.

2.Diámetro del tornillo: Φ150mm

3.Siemens Bede AC motor 110kw, Fuji frequency controller

4.The spiral cylinder and screw are made of high-strength nitriding steel, equipped with resistance heater, divided into several heating zones, including a full set of electrical control devices, including power, temperature control, pressure control, etc.. see the plasticizing capacity of electric control part for details

1.The main driving roller is made of seamless steel tube

2.Cutting speed:800-1000m/min

3. Siemens Bede AC motor, 15kw * 1 set, Fuji variable frequency controller of Japan

4.Minimum cutting width: 100 milímetros

5.Maximum winding diameter: 1000milímetros

6.Number of slitting knives 16 sets

7. 3 carbon fiber gas expansion shafts

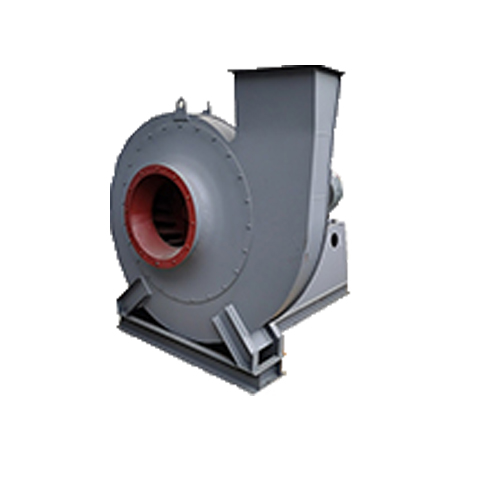

1.The speed of exhaust fan is adjustable2.Accessories: GD-SM-SO2 static mixer

3.Total air volume: 15000-23000 m³/ h

4.Air pressure regulator: Fuji Inverter(RKC-F900)

5.The fan power is 75KW * 1 set, 90kW * 1 set, including the exhaust pipe,and the suction air is discharged to the outdoor

6. The power of cold air fan is 75kw, 2sets, Siemens Bede motor is adopted

1.Power:45KW AC Motor

2.Heating: Oil Heating

4.Solicitud

APLICACIONES DE NO TEJIDOS

Guanlong Nonwoven lines are designed and manufactured in accordance with individual customer requirements. Their possible area of application is correspondingly wide.

Como :

PAQUETE – Bolsa de la compra, Envasado de arroz, embalaje de ropa, etc..

HIGIENE – pañales para bebes y adultos, Higiene femenina, etc..

MÉDICO – Máscaras de cirujano, prendas desechables, etc..

MUEBLES – Cubierta de camas, Cubierta de asientos, etc..

TÉCNICO – Geotextiles, Agricultura, etc..

FILTRACIÓN – Aire, Gas, Líquidos, etc..

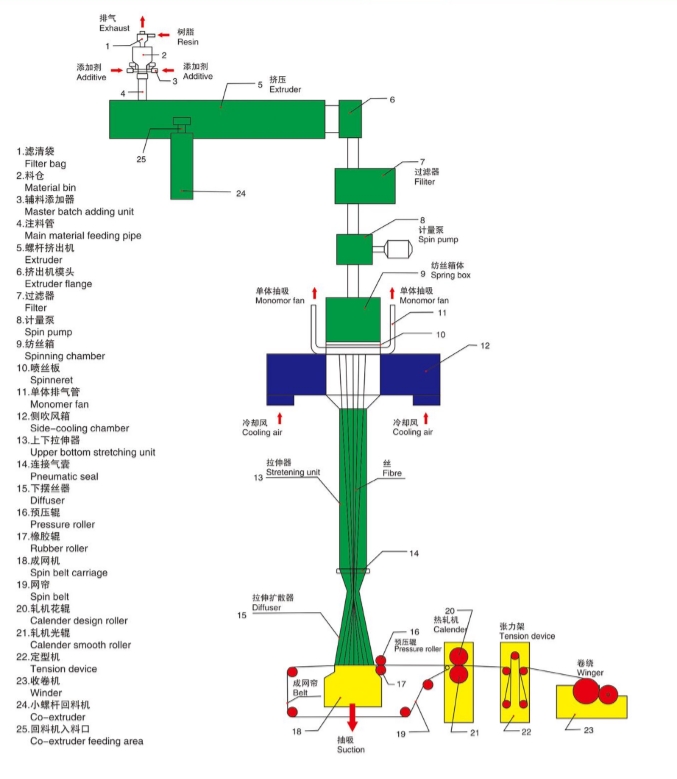

5.production process

1.This production line use “slit negative pressure draft” technology

2.Process flow: PP raw material Feeding→Extrusion Melting → Filtering →Metering→spinning→Cooling→Stretching→Web spreading→Thermal bonding →slitting→collecting

6.about us

Guanlong se adhiere primero al cliente, calidad primero, sigue superando los límites. Después de más de 10 años de práctica y exploración, Guanlong has made marked achievements in quality and obtained consistent praise in the domestic and overseas’ spunbond industry. Nuestros clientes están ubicados en varias provincias de China..

1.12 Hours—-We will give you reply within 12 hours.

2.Pre-sale service—-We provide your professional service in fluent English.

3.Delivery—-1~3 months.

4.Free Design—-Professional engineers, free designs.

5.Certificados—-The third-party verification service provider.

6.After sales service—-OEM service provide; Design service provide; Buyer label provided.

7.Packing & Shipping

Standard export packaging:

1. Apply anti-rust oil to the equipmenteasy rustypart and carry out anti-rust treatment.

2. The whole machine was wrapped with stretch film for protection,and the equipment control cabinet and other components are protected against shock with packaging materials like XPS foam board and EPE foam sheet.

3. Reinforceeasy-movepart of the equipment.

4. Put desiccant before packaging to avoid rusting equipment during sea transportation.

8.FAQ

Q1:What’s your warranty policy?

A1:The Seller will guarantee the machine for 18 months since the date of shipment(that is leaving from Seller’s factory) or the seller will guarantee the machine for 12 months since the date of starting installation and adjustment, whichever comes first.

Q2:What’s your minimum order quantity?

A2:Min order quantity:1 set or by negotiate with each other.

Q3:What package do you use for the product?

A3: Be Coated with anti-corrosion oil, and covered with plastic film, then packed in wooden box.

Q4:Do you have technical instruction if I buy your product?

A4:Please read the user manual carefully for your reference, we have detail instruction on it. If your problems still can not be solved, welcome to contact us for help.

Q5:What is your overseas service?

A5:We will provide high quality overseas service ,our technical staff will be able to provide you with technical support, for you personally to overseas assembly and test equipment.

Q6:Will you conduct training for our staff here?

A6:Yes, we will provide technology support to factory technology, training for the relative person.

P7:What are your terms of payment?

A7:We accept T/T, L/C.