Tela no tejida de GL-SSMMS PP que hace la bata quirúrgica del hospital de la máquina 380v que hace el equipo

| Ancho del producto | 3200milímetros(Ancho disponible) |

|---|---|

| Cantidad de la cabeza de la cabeza | Hilado 3 Conjuntos derretidos 2 sets |

| Negador de filamento | (S)≤1.7-2.0den (METRO)2~ 4 μ m |

| Rango de peso de tela | 10-100g/ m2 |

Descripción del Producto

1.Perfil de la empresa:

Guanlong No Textil Technology Co., Ltd en Quanzhou está especializado en la investigación,Diseño y fabricación de una línea de producción de telas no tejida y maquinaria de procesamiento no tejido desde 2017. El predecesor de Guanlong es Zhejiang General no tejido de fabricación de máquinas de fabricación, que comenzó en 2005. Ahora Guanlong ha desarrollado una serie de soluciones tecnológicas no tejidas como S, SS,SSS, SMS, SMS, Líneas de producción de SSMS y SSMMS y una variedad de selecciones de máquinas de procesamiento no tejidas.

Guanlong insiste en poner a los clientes y la calidad primero y se promete estrictamente a los clientes. En la condición de 20 años de práctica y exploración, Guanlong ha realizado notables logros de calidad y constantemente obtuvo una buena evaluación en la industria nacional y en el extranjero no tejidas. Nuestros clientes están muy extendidos en tierras chinas. Y en cuanto a clientes extranjeros, India, Indonesia, Vietnam, Bangladesh, Otras regiones del sudeste asiático y del Medio Oriente tienen la memoria de nuestra producto.

Política de la compañía de Guanlong: El producto es personalidad. ,La innovación es el motor y los clientes’ la necesidad es nuestro estándar. Invitamos calurosamente su cooperación.

2.Detalles del producto

1.Datos principales

1.1. tipo de producto:SSMMS SPUNBOND MELTBLOWN COMPUESTA COMPUESTA BECA NO tejida; Tela no tejida SSS Spunbond; M tela no tejida compuesta meltia

1.2. Ancho del producto:3200milímetros(Ancho disponible)

1.3. Die Head Qty.:Hilado 3 Conjuntos derretidos 2 sets

1.4. Negador de filamento:(S)≤1.7-2.0den (METRO)2~ 4 μ m

1.5. Rango de peso de tela:10-100g/ m2

1.6. Máximo. Velocidad de producción:600m/min

1.7. Capacidad:9000-1000T/año

1.8. Consumo eléctrico(promedio):SSMMS < 1600 grados/t; SSS < 800-1100 grados/t

2. Descripción del Producto

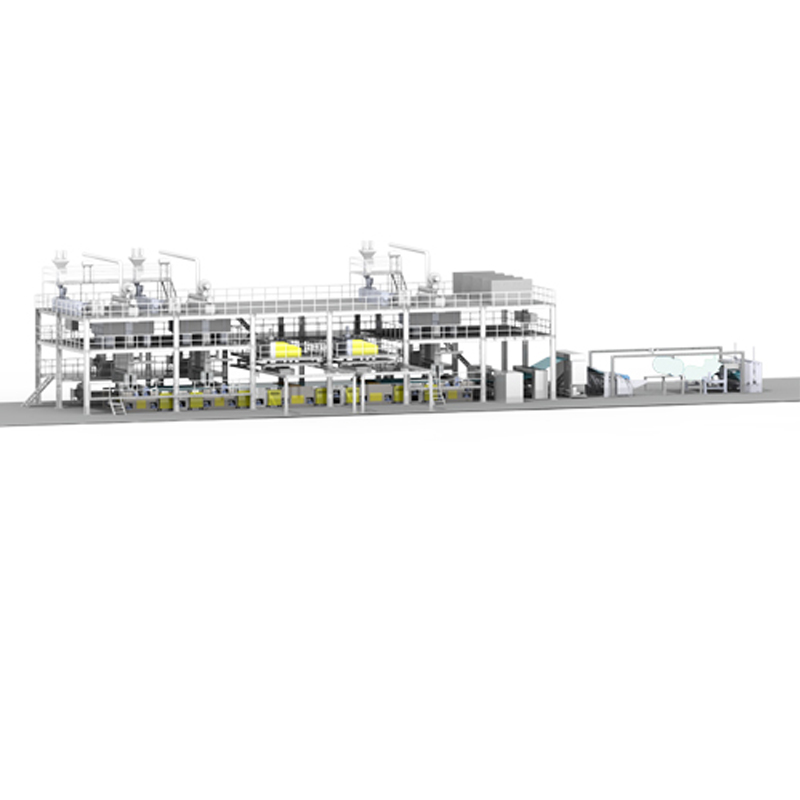

SSMMS Spunmelt Machine no tejido es una línea compuesta para la producción no tejida que combina la técnica de fabricación Spunbond y Meltblown. It has five beams in production and can be customized for you according to your demands of production.

Adopta un gabinete de control eléctrico inteligente y un sistema de dibujo giratorio.. El modo de control del sistema presenta una velocidad avanzada de frecuencia modulada de CA., comunicaciones sincronizadas totalmente digitales.

SSMMS Spunmelt Nonwoven Machine is manufactured for PP composite non-woven fabrics. Después de la entrada de materias primas., Pasar por extrusión y fusión., filtración, medida, hilado, enfriamiento, extensión, difusión web, Unión térmica y corte según los requisitos y luego empaquetado para almacenamiento y entrega..

3.Partes principales

1.Presión de trabajo máxima: 16MPA

2.Temperatura de trabajo máxima: 310℃

3.Área de filtro de un solo cilindro: 0.5-19㎡

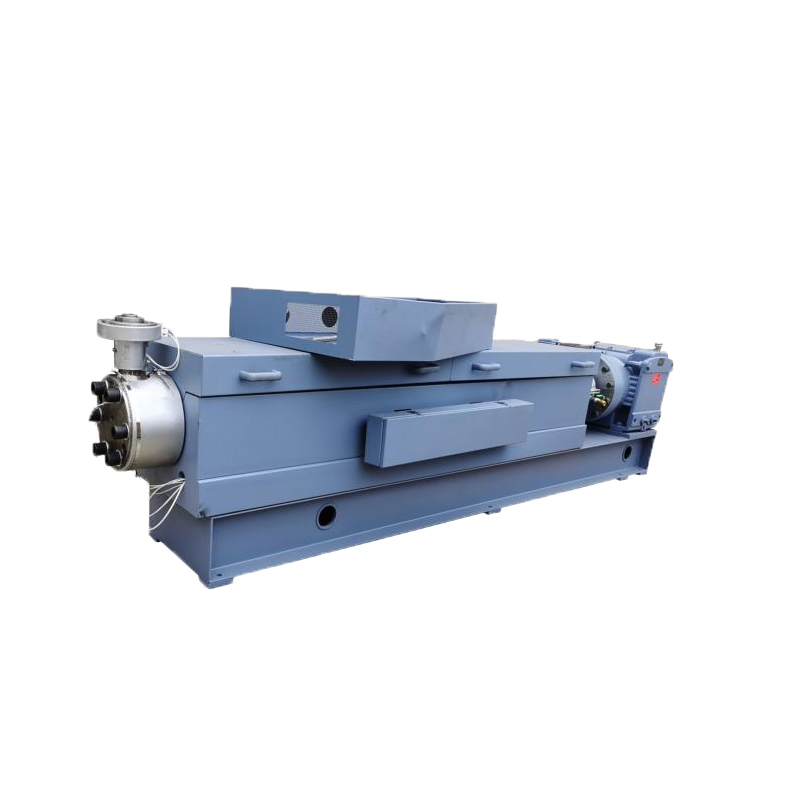

1. Relación de aspecto L/D = 30:1.

2.Diámetro del tornillo: Φ150 mm

3.Siemens Bede AC Motor 110kW, Controlador de frecuencia de Fuji

4.El cilindro espiral y el tornillo están hechos de acero nitrurro de alta resistencia, equipado con calentador de resistencia, dividido en varias zonas de calentamiento, incluyendo un conjunto completo de dispositivos de control eléctrico, incluyendo poder, control de temperatura, control de presión, etc.. Consulte la capacidad de plastificación de la parte de control eléctrico para más detalles

1.El principal rodillo de conducción está hecho de tubo de acero sin costura

2.Velocidad de corte:800-1000m/min

3. Siemens rezó AC motor, 15KW * 1 colocar, Controlador de frecuencia variable de Fuji de Japón

4.Ancho de corte mínimo: 100 milímetros

5.Diámetro máximo de devanado: 1000milímetros

6.Número de cuchillos para cortar 16 sets

7. 3 Pañales de expansión de gas de fibra de carbono

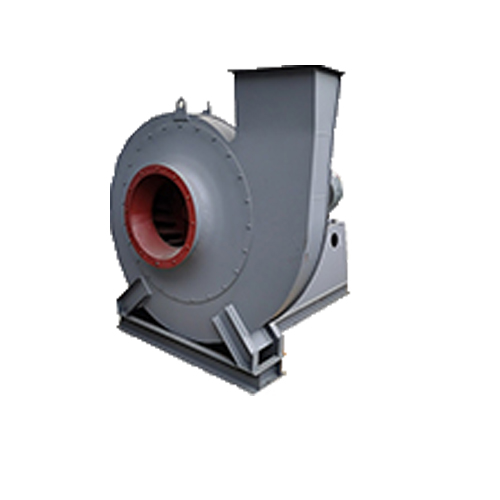

1.La velocidad del ventilador de escape es ajustable2.accesorios: GD-SM-SO2 MECHA ESTÁTICO

3.Volumen de aire total: 15000-23000 m³/ h

4.Regulador de presión del aire: Fuji Inverter (RKC-F900)

5.La potencia del ventilador es de 75kw * 1 colocar, 90KW * 1 colocar, incluyendo el tubo de escape, y el aire de succión se descarga al aire libre

6. El poder del ventilador de aire frío es de 75kw, 2sets, Se adopte el motor Siemens Bede