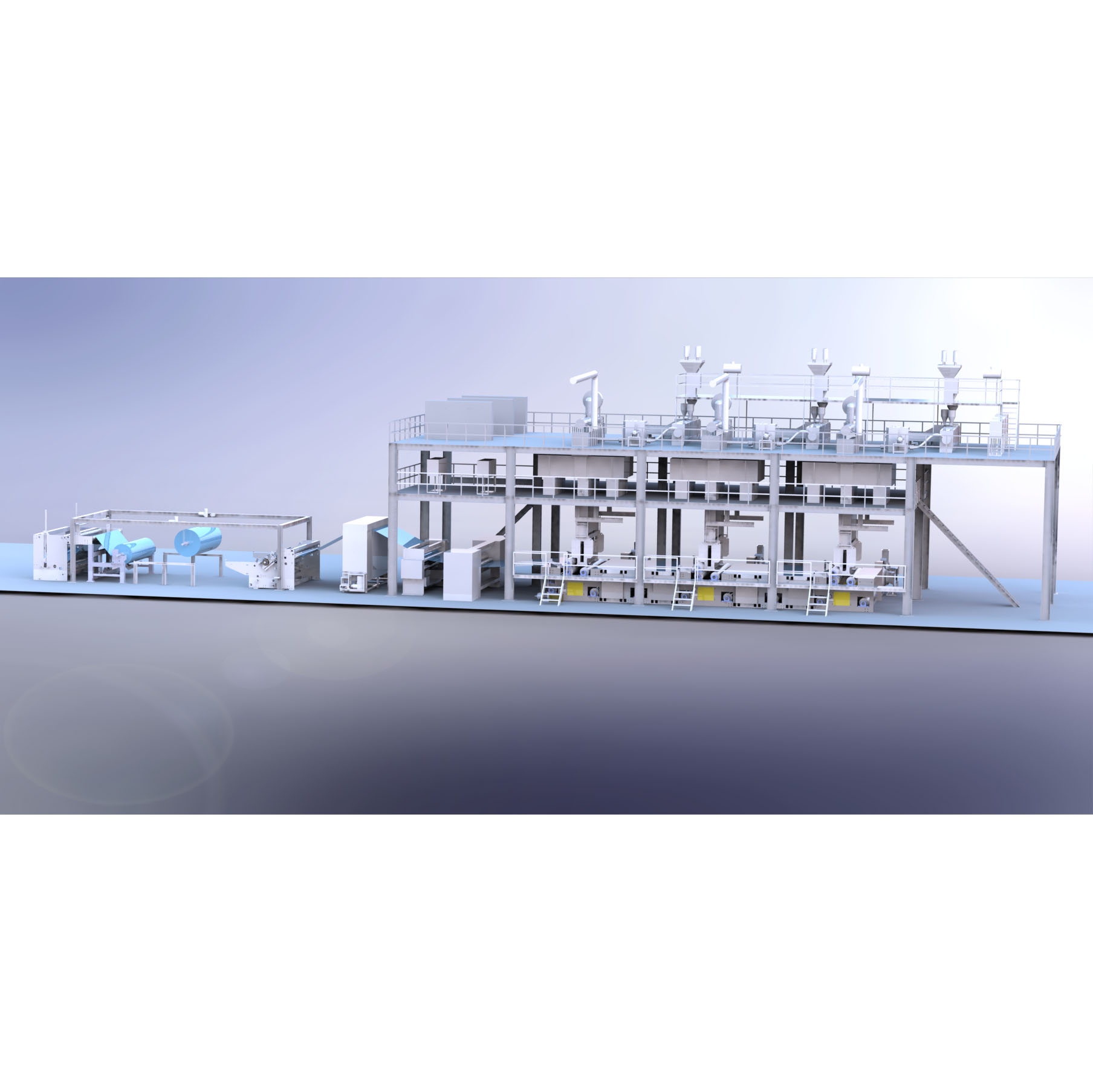

Comprensión de la línea de producción de telas no tejidas hiladas: A Symphony of Precision

Spunbonded nonwovens production lines are specialized machinery designed to produce spunbonded nonwoven fabrics. El proceso implica varias etapas clave.:

1. Extrusión de polímeros: Molten polymer, typically polypropylene or polyethylene, is extruded through spinnerets into fine filaments.

2. Fiber Formation: As the filaments emerge from the spinnerets, they are stretched and cooled, forming continuous fibers.

3. Formación web: The fibers are deposited onto a moving conveyor belt, forming a continuous web of nonwoven fabric.

4. Vinculación: The web is then bonded together using heat, chemical binders, or mechanical entanglement to create a cohesive fabric.

5. Finishing: The nonwoven fabric undergoes finishing processes such as calendering, embossing, or coating to achieve desired properties and characteristics.

Spunbonded Nonwovens Production Line Features: Innovation and Efficiency

Spunbonded nonwovens production lines incorporate advanced features that enhance efficiency, productivity, and fabric quality:

1. High Production Capacity: These production lines are capable of producing large quantities of nonwoven fabric in a continuous process, catering to the demands of large-scale production.

2. Automation: Automation systems minimize manual labor, ensuring consistent product quality and reducing production costs.

3. Customizable Designs: Many production lines offer customizable options, allowing manufacturers to tailor the fabric’s properties, such as weight, espesor, and fiber composition, to meet specific requirements.

4. Energy Efficiency: Modern production lines incorporate energy-efficient technologies to minimize energy consumption and reduce environmental impact.

5. Quality Control: Rigorous quality control measures ensure that the produced nonwoven fabrics meet the desired standards and specifications.

The Diverse Applications of Spunbonded Nonwovens Production Line: A Versatile Material

Spunbonded nonwoven fabrics find applications in a wide range of industries due to their unique properties:

1. Hygiene and Medical: Disposable medical gowns, surgical drapes, and hygiene products utilize spunbonded nonwovens for their sterility, blandura, y propiedades de barrera.

2. Filtración: Spunbonded nonwovens are used in air and liquid filtration systems, effectively removing particles and contaminants.

3. embalaje: Nonwoven fabrics are employed in packaging materials, providing cushioning, protection, and tamper-evident features.

4. Agricultura: Spunbonded nonwovens serve as weed barriers, crop covers, and frost protection in agricultural applications.

5. Automotive: Nonwoven fabrics are used in automotive interiors, sound insulation, y sistemas de filtración.

6. Construcción: Spunbonded nonwovens are utilized as underlayments, roofing membranes, and insulation materials.

Spunbonded nonwovens fabric making machines stand as a testament to the ingenuity and innovation in the textile industry. By understanding the features, applications, and remarkable properties of spunbonded nonwoven fabrics, businesses can harness their potential to create a diverse range of products that cater to various industries. Embrace the power of spunbonded nonwovens production lines and unlock new possibilities in fabric manufacturing.