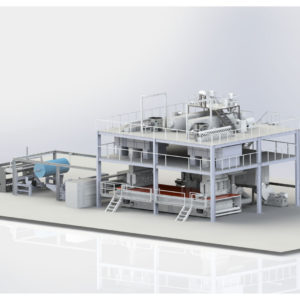

PP SS Spunbond Machine

A PP SS (polypropylene spunbond) machine is a type of nonwoven fabric production machine used to create fabrics from polypropylene resin. The process involves melting and extruding the polypropylene resin, which is then spun into filaments, and subsequently laid down in a web-like formation to create a nonwoven fabric.

The “SS” in PP SS machine stands for “spunbond/spunbond,” which refers to the double-layered web formation created by the machine. This type of nonwoven fabric is commonly used in a variety of applications, including as a lightweight, breathable material for disposable medical gowns, face masks, and other protective gear, as well as for agricultural coverings, geotextiles, and other industrial applications.

PP SS machines typically consist of several key components, including an extruder for melting and spinning the polypropylene resin, a spinning beam for directing the filaments onto a moving conveyor belt, and a bonding system for fusing the filaments together into a cohesive web. The machine may also include additional equipment for cutting, winding, and finishing the fabric.

Overall, PP SS machines play an important role in the production of nonwoven fabrics, which are widely used in a range of industries and applications.

Showing all 7 results

-

Double Beams SS 100% PP Spunbond Nonwoven Fabric Machine for Spun Bond SS Fabric

-

SS Double Beams High Capacity and Speed Spunbond Non Woven Fabric Machine

-

Most Advanced SS Non Woven Fabric Making Machine Hot Sell SS Double Beams Production Line

-

2400mm SS Nonwoven Cloth Production Line Nonwoven Fabric Making Machine For Bag

-

Hot Sell SS PP Spunbonded Non Woven Fabric Making Machine

-

Double S Nonwoven Fabric Production Line

-

PP SS Spunbond Nonwoven Fabric Making Machine