abril 21, 2025 | Notícias

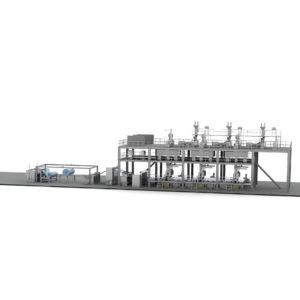

Nos últimos anos, a demanda por produtos de tecido não tecido disparou devido às suas aplicações versáteis em vários setores, especialmente na área da saúde, higiene, e setores de filtração. Tecidos não tecidos, conhecido por sua durabilidade, leve, e...

Novembro 19, 2024 | Notícias

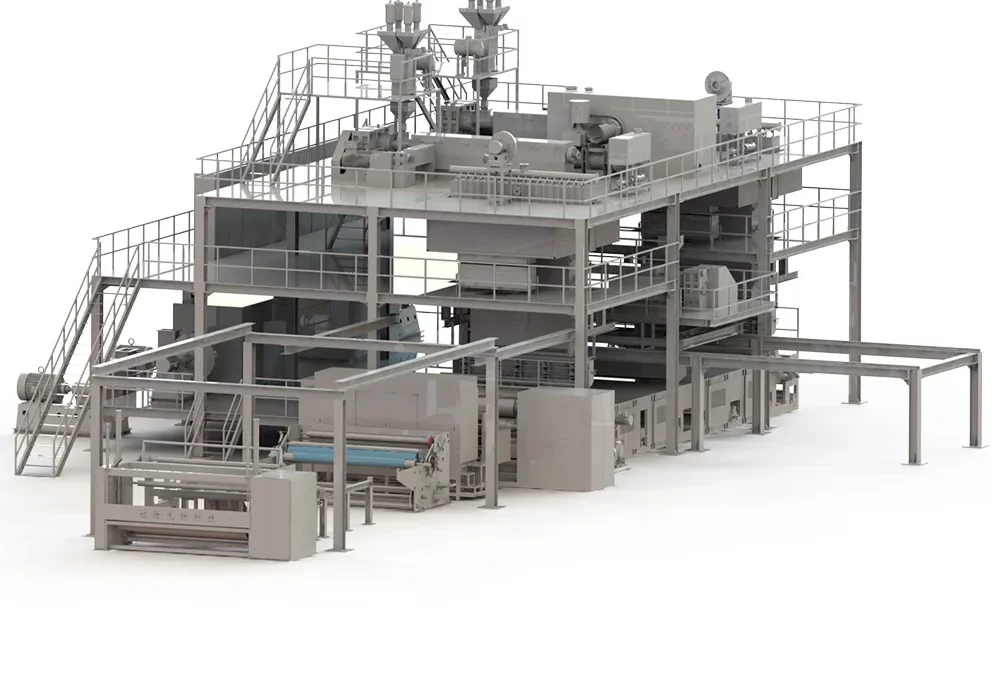

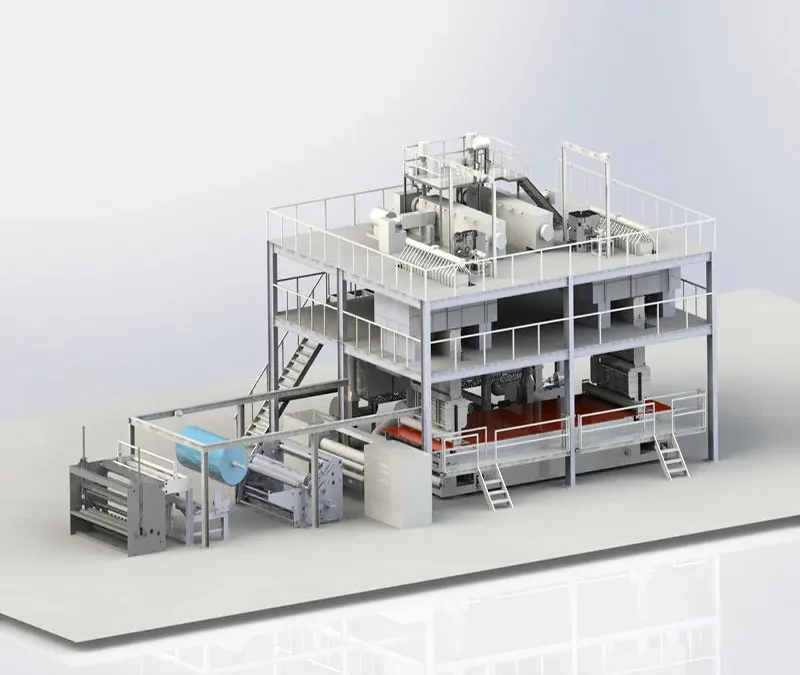

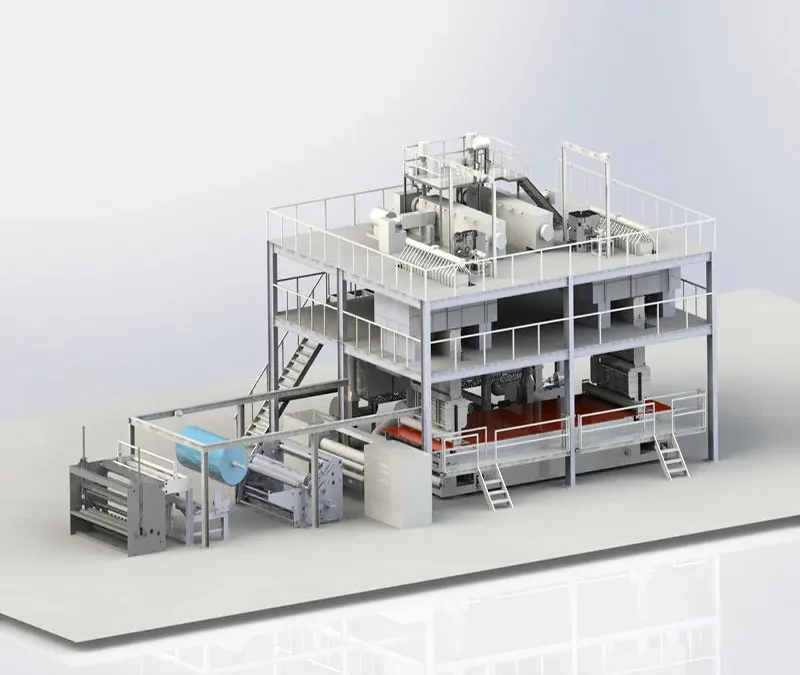

Uma máquina de fabricação de tecidos não tecidos PP Spunbond não é uma ferramenta essencial para produzir tecidos não tecidos de alta qualidade a partir de polipropileno. Esses tecidos são amplamente utilizados em diversas indústrias devido à sua força, durabilidade, e versatilidade. Let’s explore the key...

Novembro 11, 2024 | Notícias

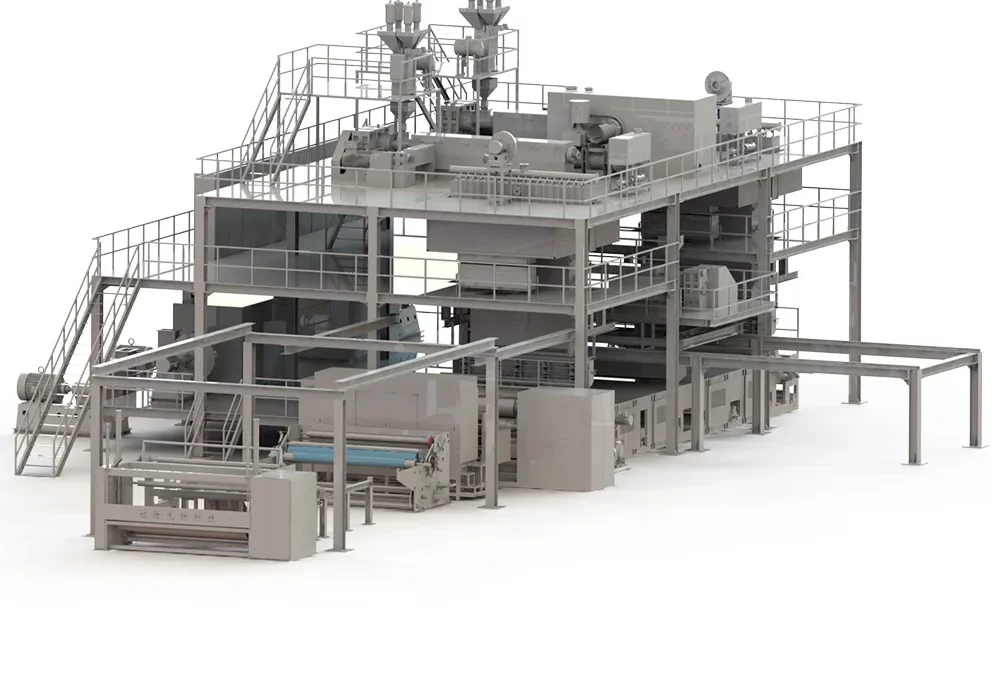

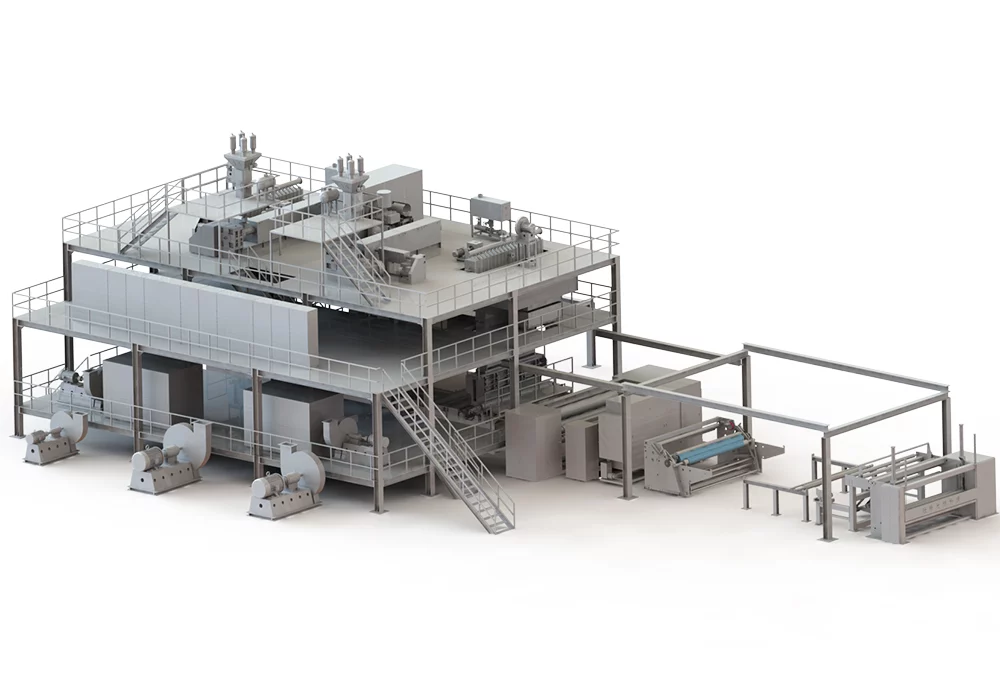

Are you looking for the best nonwoven fabric machine for your business? A escolha certa pode fazer uma enorme diferença na eficiência da sua produção e na qualidade do produto. Máquinas não tecidas, como a máquina PP SS Spunbond, are essential for creating high-quality...

Outubro 27, 2024 | Notícias

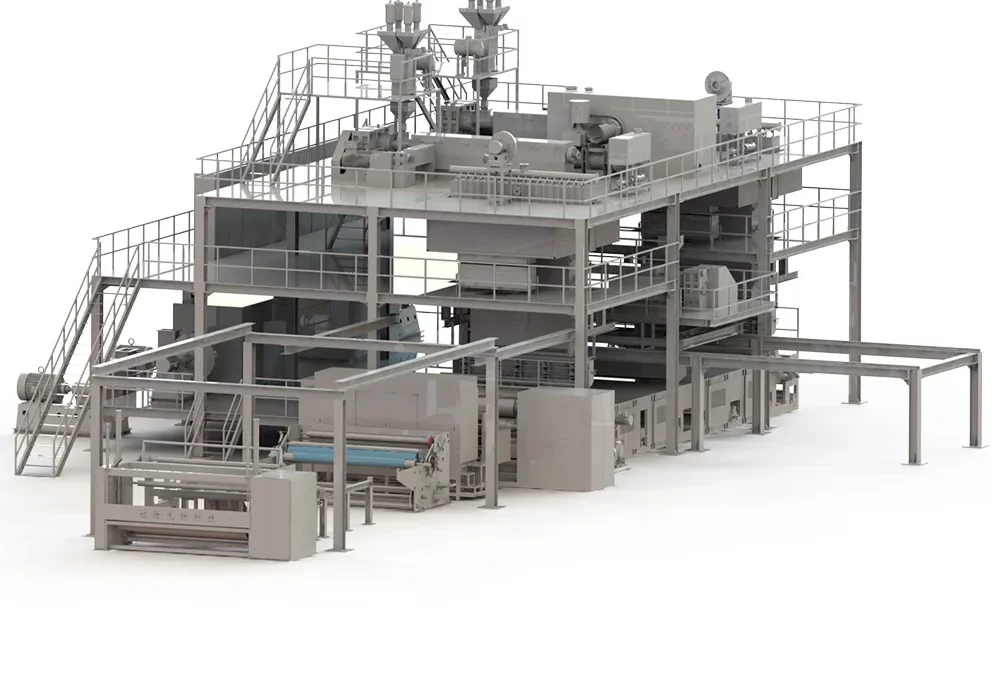

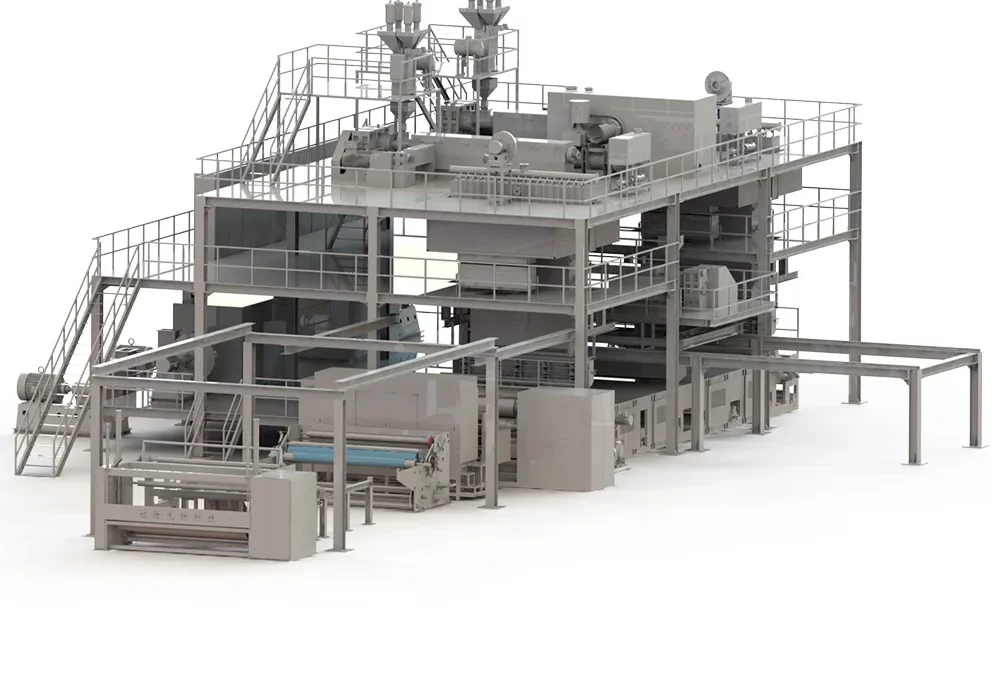

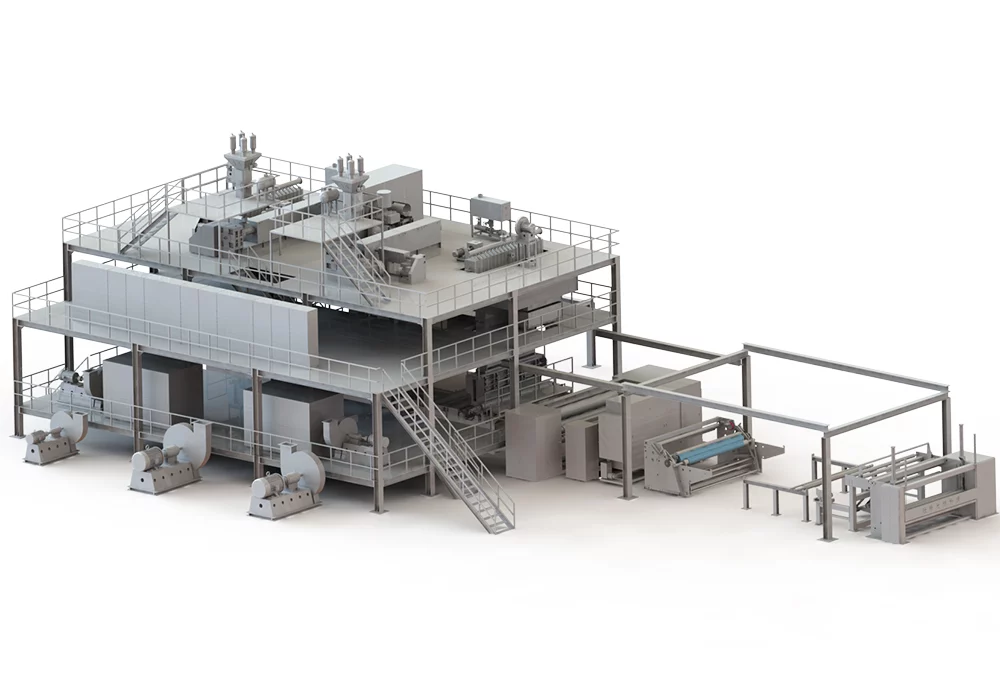

Você está procurando um fabricante confiável de máquinas de não tecido para aprimorar sua produção de tecidos?? O mercado de máquinas para fabricar tecidos é vasto, com inúmeras opções disponíveis. Este artigo explora os recursos de destaque de máquinas não tecidas S de alta qualidade, garantindo...