Descrição do produto

1.Perfil de companhia:

Guanlong tem se concentrado em máquinas para fabricar tecido não tecido ao longo de 15 anos. Combinamos tecnologia avançada internacional e fornecemos diversas soluções holísticas de linhas de produção para clientes de acordo com sua solicitação.

Até aqui,fabricamos centenas de linhas de produção totalmente automáticas para clientes da Índia, Indonésia, Filipinas, Nepal, Rússia e outros países.

2.Detalhes do produto

2-1.Dados principais

1.1. tipo de produto

SMS Spunbond Meltblown Composite não tecido não tecido,SS Spunbond não tecido não tecido fascinante

M Meltblown não tecido não tecido

1.2. Largura do produto:3200mm (Largura padrão após aparar)

1.3. Número de cabeças: 2 Conjuntos de Spunbond, 2 Conjunto de MeltBlown

1.4. Finidade da fibra: Sistema Spunbond ≤1.6-2.0den, Sistema de derretimento: 2~ 5μ m

1.5.Faixa de peso do tecido:10-150g/m2

1.6. Velocidade máxima de produção: 600m/min

1.7. Produção anual: 4500 toneladas/ano

2. Descrição do produto

SMMS Spunmelt Nonwoven Machine é uma linha composta para produção não tecida que combina a técnica de fabricação Spunbond e MeltBlown. Possui quatro vigas na produção e pode ser personalizado para você de acordo com suas demandas de produção.

Adota um gabinete de controle elétrico inteligente e um sistema de desenho giratório. O modo de controle do sistema apresenta velocidade modulada em frequência CA avançada, comunicações sincronizadas totalmente digitais.

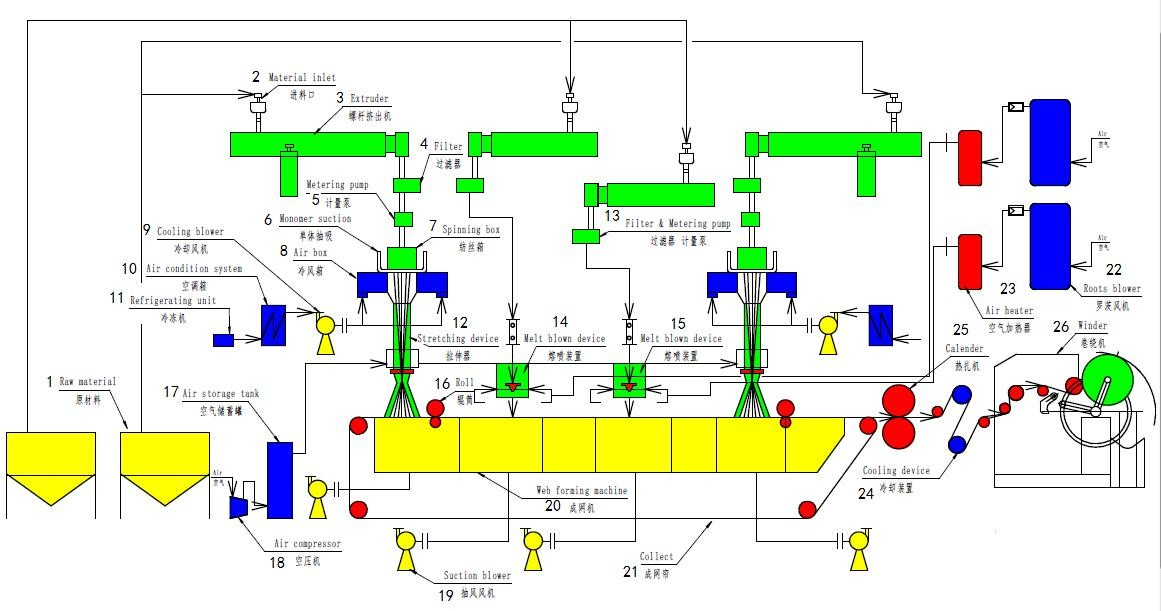

2-3.fluxo de produção

SMMS Spunmelt Nonwoven Machine é fabricada para tecidos não tecidos compostos PP. Após a entrada de matérias-primas, passar por fusão por extrusão, filtragem, medição, fiação, resfriamento, alongamento, divulgação na web, ligação térmica e corte conforme requisitos e depois embalado para armazenamento e entrega.

2-4.a especificação da máquina SMMS

3.Partes principais

3-1 Extrusora de parafuso

1. Proporção L/D=30:1.

2.Diâmetro do parafuso: Φ150mm

3.Motor AC Siemens Bede 110kw, Controlador de frequência Fuji

4.O cilindro espiral e o parafuso são feitos de aço de nitretação de alta resistência, equipado com aquecedor de resistência, dividido em várias zonas de aquecimento, incluindo um conjunto completo de dispositivos de controle elétrico, incluindo poder, controle de temperatura, controle de pressão, etc.. veja a capacidade de plastificação da peça de controle elétrico para obter detalhes

3-2 Caixa de fiação com sistema de aquecimento

1)Cada caixa giratória pode distribuir o derretimento simetricamente e equivalente

2)O pipeline de fusão adota a carcaça composta e o aquecimento elétrico

3)A potência de aquecimento do forno de óleo condutor de calor é de 48kW; A temperatura máxima de aquecimento é 300 graus, e é aquecido fora do forno a óleo.

3-3 Componentes giratórios e giratórios

1)É feito de aço resistente a alta temperatura de alta temperatura, 2800 * 256 em comprimento, A abertura é de 45s /4 pares, e o spinneret contém sobre 15600 buracos (Parâmetros específicos estão sujeitos ao fabricante).

2)Cada conjunto de componentes inclui: Lavadora de alumínio, placa de distribuição, Tela de filtro de aço inoxidável com revestimento de várias camadas de alumínio

3-4 Refrescando o ar soprando (para cima e para baixo) dispositivo de desenho

1)O sistema de desenho superior adota uma forma totalmente fechada, e está equipado com o dispositivo spinneret de elevação hidráulica.

2)A camada interna do vidro temperado do plano, 12mm de espessura, adota tecnologia de fenda

3)É dividido em canal de rascunho, canal de difusão, dispositivo móvel. O sistema de tensão inferior está conectado ao sistema de tensão superior. É feito de aço inoxidável de alta qualidade e possui um mecanismo de ajuste

4)Quantidade total de ar de sucção: 25000m³/h, temperatura do ar 20-30 ℃

5)A superfície externa dos dispositivos de desenho superior e inferior é fornecida com uma camada isolante

4.Nossa vantagem:

4-1. Temos vendas e engenheiros profissionais, estão prontos para enviar peças de reparo de emergência em 24 horas, peças facilmente danificadas em 5 dias com conhecimento profissional.

4-2. Nós nos concentramos no atendimento ao cliente, Durante todo o ano, serviço ininterrupto, treinamento pessoal e assim por diante.

4-3. Não apenas forneça atendimento ao cliente, Mas também o sistema pré-vendas,

incluindo solução para a seleção de produtos, armazenamento de peças, Orientação técnica, treinamento operacional, plataforma de gerenciamento de troca e assim por diante.

4-4.Percebendo a ideia de focar no sucesso do cliente, Criando valor para o cliente.

5. Aplicativo

Suprimentos médicos: roupas cirúrgicas, máscaras, roupas de isolamento, roupas de paciente, sacos, etc..

Suprimentos de proteção ao trabalho: roupas de proteção, automóveis, Tampas de motocicleta, Tampas de poeira, Maclão de tinta spray, Capatos de chuva, etc..

Bens de viagem: guarda -chuvas de praia, roupas de praia, sacos de reciclagem, etc..

Limpeza de suprimentos: fraldas para bebês, almofadas de incontinência de adultos, absorventes higiênicos, Filtrar produtos, etc.;

6.Certificado

7.Perguntas frequentes

1º trimestre:Qual é o prazo de garantia e garantia da sua empresa?

A1:12 meses após a instalação terminada na máquina

2º trimestre:Podemos escolher diferentes marcas de peças ? Podemos personalizar a máquina de acordo com nossa necessidade ?

A2:Sim, Nosso equipamento é personalizado e pode ser projetado de acordo com seus requisitos.

3º trimestre:Quanto tempo leva para produzir a máquina?

A3:Como temos um tipo diferente de máquina de tecido não tecida, como S/SS/SSS/SMS/SMMS Line, Portanto, o tempo de entrega é diferente. normalmente ,O tempo de entrega é 8 mês após confirmar o pagamento.