Descrição do produto

1.Perfil de companhia:

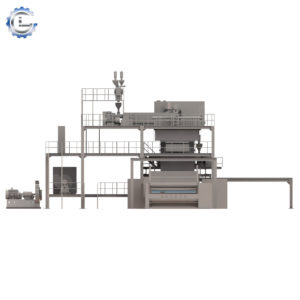

2.Detalhes do produto

2-1:Main Technology data

1.Fabric width:1600mm(Availed width)

2.Diâmetro máximo do enrolamento:Φ1500MM

3.Capacidade:According70 g/㎡,9-10t/24h

4.Monofilament size:<2.5d

5.Fabric weight:10~200 g/㎡

6.Designed speed:150M/MIN ;(Working speed:130 M/MIN)

7.Tamanho do equipamento:length 15 *width10* height 11

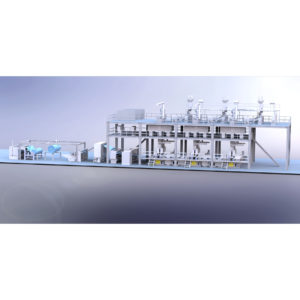

The following word will introduce the features of S Spunbond Nonwoven Machine:

1. S Spunbond Nonwoven Machine adopts an intelligent electrical control cabinet and spinning drafting system. O modo de controle do sistema apresenta velocidade modulada em frequência CA avançada, comunicações sincronizadas totalmente digitais.

2. S Spunbond Nonwoven Machine is featured by lower investment, compact construction, small covering area, and labor-saving.

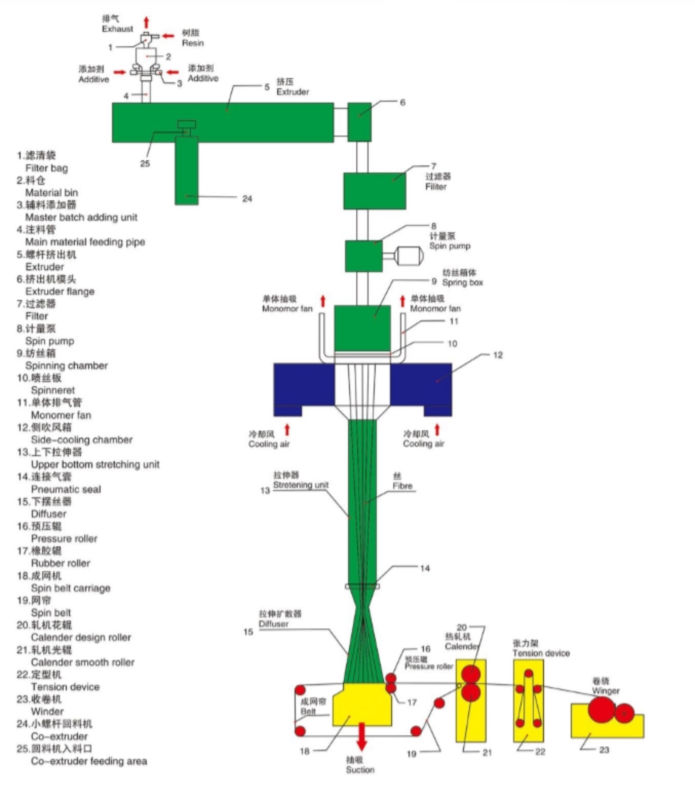

3. S Spunbond Nonwoven Machine is a single-beam professional manufacturer of single-layer nonwoven fabric equipment which is manufactured for PP/PET/PLA/Bi-Component Spunbond nonwoven fabrics’ Produção. Após a entrada de matérias-primas, passar pelo processo de extrusão, fiação, têmpera, alongamento de ar de fechamento, formação de teia, calendário, enrolamento e corte conforme requisitos e depois embalado para armazenamento e entrega.

4. As the fabrics have great intensity, good breath-ability, and good feeling, they are widely used for various fields such as home decoration, furniture covers, clothing shoe leather, capas de proteção industriais e agrícolas, medical and sanitary supplies, beauty products and so on.

2-3 Parâmetro técnico

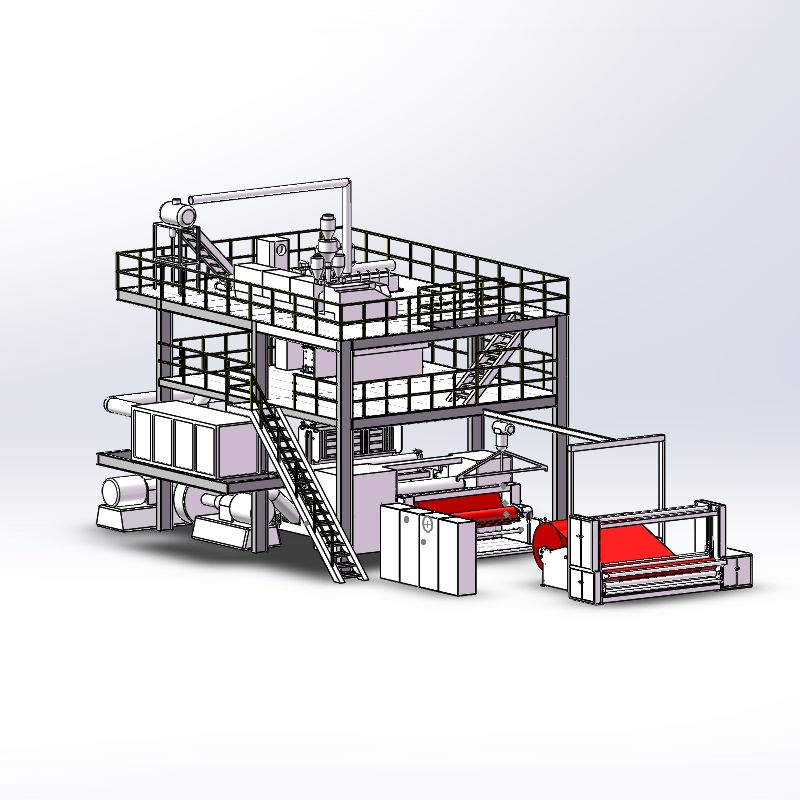

3.Partes principais

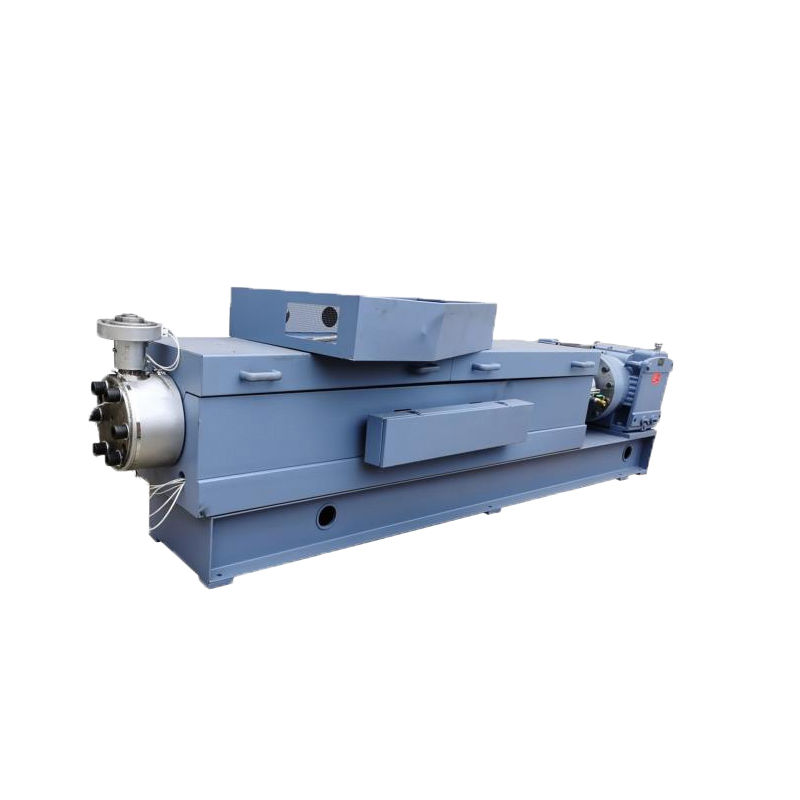

1.Pressão máxima de trabalho: 16MPa

2.Temperatura máxima de trabalho: 310℃

3.Área de filtro de cilindro único: 0.5-19㎡

1. Proporção L/D=30:1.

2.Diâmetro do parafuso: Φ150mm

3.Motor AC Siemens Bede 110kw, Controlador de frequência Fuji

4.O cilindro espiral e o parafuso são feitos de aço de nitretação de alta resistência, equipado com aquecedor de resistência, dividido em várias zonas de aquecimento, incluindo um conjunto completo de dispositivos de controle elétrico, incluindo poder, controle de temperatura, controle de pressão, etc.. veja a capacidade de plastificação da peça de controle elétrico para obter detalhes

1.O rolo principal é feito de tubo de aço sem costura

2.Velocidade de corte:800-1000m/min

3. Motor AC Siemens Bede, 15kw * 1 definir, Controlador de frequência variável Fuji do Japão

4.Largura mínima de corte: 100 milímetros

5.Diâmetro máximo do enrolamento: 1000milímetros

6.Número de facas de corte 16 conjuntos

7. 3 eixos de expansão de gás de fibra de carbono

1.A velocidade do exaustor é ajustável2.Acessórios: Misturador estático GD-SM-SO2

3.Volume total de ar: 15000-23000 m³/h

4.Regulador de pressão de ar: Inversor Fuji(RKC-F900)

5.A potência do ventilador é 75KW * 1 definir, 90kW * 1 definir, incluindo o tubo de escape,e o ar de sucção é descarregado para o exterior

6. A potência do ventilador de ar frio é de 75kw, 2conjuntos, Motor Siemens Bede é adotado

1.Poder:45KW AC Motor

2.Heating: Oil Heating

1.Each spinning box can distribute the melt symmetrically and equivalently

2. The melt pipeline adopts compound casing and electric heating

3. The heating power of the heat-conducting oil furnace is 48KW; the maximum heating temperature is 300 degrees, and it is heated outside the oil furnace.

4.Aplicativo

NONWOVENS APPLICATIONS

Guanlong Nonwoven lines are designed and manufactured in accordance with individual customer requirements. Their possible area of application is correspondingly wide.

Such as :

PACOTE – Bolsa de compras, Embalagem de arroz, Embalagem de roupas, etc..

HIGIENE – Fraldas para bebês e adultos, Higiene feminina, etc..

MÉDICO – Máscaras de cirurgião, Roupas descartáveis, etc..

MOBÍLIA – Capa de cama, Cobertura de assentos, etc..

TÉCNICO – Geotêxteis, Agricultura, etc..

FILTRAÇÃO – Ar, Gás, Líquidos, etc..

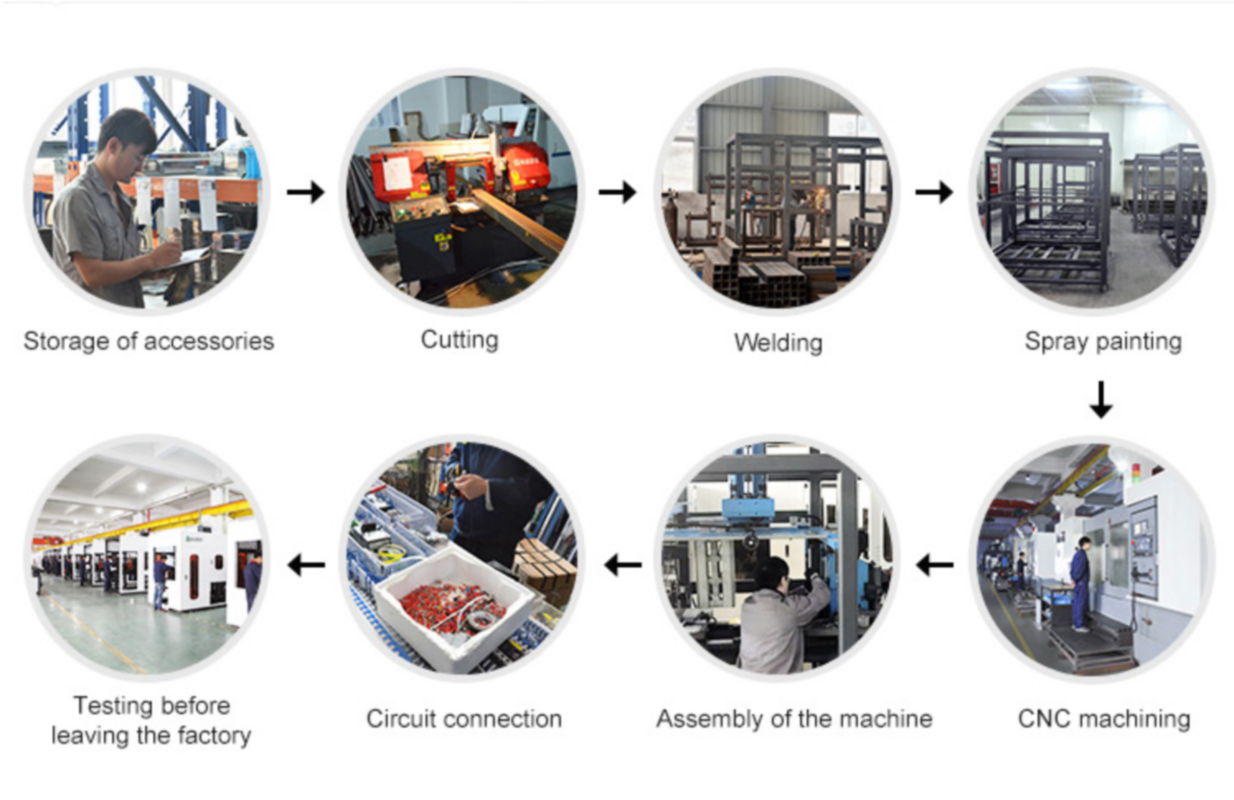

5.production process

6.nosso serviço

1.12 Hours—-We will give you reply within 12 horas.

2.Pre-sale service—-We provide your professional service in fluent English.

3.Delivery—-1~3 months.

4.Free Design—-Professional engineers, free designs.

5.Certificados—-The third-party verification service provider.

6.After sales service—-OEM service provide; Design service provide; Buyer label provided.

7.Embalagem & Envio

Standard export packaging:

1. Apply anti-rust oil to the equipmenteasy rustypart and carry out anti-rust treatment.

2. The whole machine was wrapped with stretch film for protection,and the equipment control cabinet and other components are protected against shock with packaging materials like XPS foam board and EPE foam sheet.

3. Reinforceeasy-movepart of the equipment.

4. Put desiccant before packaging to avoid rusting equipment during sea transportation.

8.Perguntas frequentes

1º trimestre:What’s your warranty policy?

A1:The Seller will guarantee the machine for 18 months since the date of shipment(that is leaving from Seller’s factory) or the seller will guarantee the machine for 12 months since the date of starting installation and adjustment, o que ocorrer primeiro.

2º trimestre:What’s your minimum order quantity?

A2:Min order quantity:1 set or by negotiate with each other.

3º trimestre:What package do you use for the product?

A3: Be Coated with anti-corrosion oil, and covered with plastic film, then packed in wooden box.

Q4:Do you have technical instruction if I buy your product?

A4:Please read the user manual carefully for your reference, we have detail instruction on it. If your problems still can not be solved, welcome to contact us for help.

Q5:What is your overseas service?

A5:We will provide high quality overseas service ,our technical staff will be able to provide you with technical support, for you personally to overseas assembly and test equipment.

Q6:Will you conduct training for our staff here?

A6:Sim, we will provide technology support to factory technology, training for the relative person.

Q7:What are your terms of payment?

A7:We accept T/T, L/C.