Descrição do produto

Guanlong has been focusing on non woven fabric production Lines for 15 anos. We combine global advanced technology and the demand of customers’ Produção, provider and customize various holistic solutions for customers. We have manufactured hundreds of full-automatic production lines for customers worldwide.

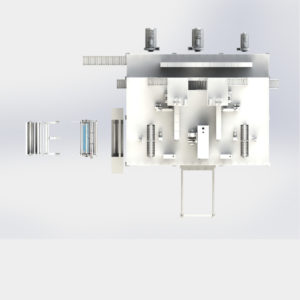

Let’s discuss about the advantages of SSMS Spunmelt Nonwoven Machine.

1. Sobre o projeto:

SSMS Spunmelt Nonwoven Machine is a composite line for nonwoven production which combines spunbond and meltblown manufacturing technique. SSMS Spunmelt Nonwoven Machine has four beams in production and can be customized for you according to your demands of production.

Adota um gabinete de controle elétrico inteligente e um sistema de desenho giratório. O modo de controle do sistema apresenta velocidade modulada em frequência CA avançada, comunicações sincronizadas totalmente digitais.

2. Sobre o processo de produção:

SSMS Spunmelt Nonwoven Machine is manufactured for PP/PET/PLA/Bi-Component spunmelt composite non-woven fabrics. Após a entrada de matérias-primas, passar por fusão por extrusão, filtragem, medição, fiação, resfriamento, alongamento, divulgação na web, ligação térmica e corte conforme requisitos e depois embalado para armazenamento e entrega.

3. Sobre os produtos de tecidos:

SSMS Nonwoven fabric is featured by excellent filtration, good breath-ability, and feeling, is widely used in the hygiene & medical industry to make surgical drapes, surgical packs, surgical gowns, disposable diapers, feminine care products, face masks and so on.

The main specifications of SSMS Spunmelt Nonwoven Machine:

process flow:

Feeding→Extrusion Melting→filtering→metering→spinning→Cooling→Stretching →Web spreading→Thermal bonding→slitting→collecting

The performance parameters are as follows:

1.Total installed capacity of production line: 450KW

2.Actual power consumption: 220 ~ 280KW / hour

3.Mechanical linear speed: 4-20eu / min

4.Width of finished product: 1600milímetros

5.Peso do Produto: 8 ~ 120g / m2

6. Meltblown fiber: 2 ~ 5μm

7.CV of uniformity: ≤4%

8.Roll maximum diameter: 600milímetros

9. Maximum annual output: wire diameter: 330 years at 2 ~ 5μm.

10 The machine covers an area of about 15000mm * 5000milímetros * H5000mm,

11.Machine weight: about 13 toneladas (based on actual weight)

(1) 12. (Voltage: three-phase power 380V50Hz)

1.) Number of workers operating the production line:

Production is divided into two shifts of 3 people each: 1 auxiliary worker, 2 technical staff

2.) Equipment configuration is as follows:

3.1 host hopper (material: stainless steel, window with material level and insert plate,)

A vacuum automatic feeding machine, control power: 3KW

3.2 Extruder: φ90 extruder set (φ90 barrel and screw host platform)

1 set of 90mm barrel

Material: 38 CrMoLALA (high quality nitrided steel)

Nitriding hardness: 740HV

Nitrided layer depth: 0.5-0.8milímetros

Diâmetro do parafuso: φ90mm

Screw aspect ratio: 30: 1

Screw form: special screw (suitable for PP solution spraying)

Material: 38rMo (high quality nitrided steel)

Nitriding hardness: 740HV

1 Set of host gearbox

Host motor power: 45KW

Control form: AC variable frequency control

Host heating zone: zone 5

Heating power per zone: 6.0KW (cast copper heater)

Total heating power: 32.5KW

Cooling method: air cooling

Air-cooled zone: Zone 5

Air cooling power per zone: 180W

4.) One set of single-channel dual-position hydraulic quick-change screen for the host (plate type)

Control method: hydraulic control

Control power: 2.2KW

Hydraulic cylinder bore: φ100mm