Os tecidos não tecidos são amplamente utilizados em diversas indústrias. Inclui cuidados de saúde, automotivo, agricultura, e mobiliário doméstico. Eles são feitos de fibras ou filamentos unidos por meio de processos mecânicos., térmico, ou processos químicos, sem o uso de tecelagem ou tricô. Os tecidos não tecidos têm diversas vantagens em relação aos tecidos tradicionais ou de malha. Como alta absorção, repelência a líquidos, respirabilidade, suavidade, e durabilidade.

A produção de tecidos não tecidos envolve diversos processos. Inclui preparação de fibra, formação de teia, colagem de teia, e acabamento. As máquinas de tecido não tecido são projetadas para realizar esses processos de forma eficiente e eficaz. Neste post, discutiremos as máquinas essenciais de tecido não tecido: o máquina de fusão, a máquina de tecido não tecido e a linha de produção de não-tecidos fiados.

Máquina soprada por fusão sempre a importância

A máquina soprada por fusão usada para produzir tecidos não tecidos soprados por fusão. Os tecidos fundidos são feitos pela fusão e extrusão de polímeros termoplásticos. Como polipropileno, em fibras finas, que são então resfriados e unidos para formar uma teia. Os tecidos fundidos têm alta eficiência de filtração. Adicionalmente, eles são amplamente utilizados em aplicações médicas e de higiene. Como máscaras cirúrgicas, Respiradores N95, e batas cirúrgicas.

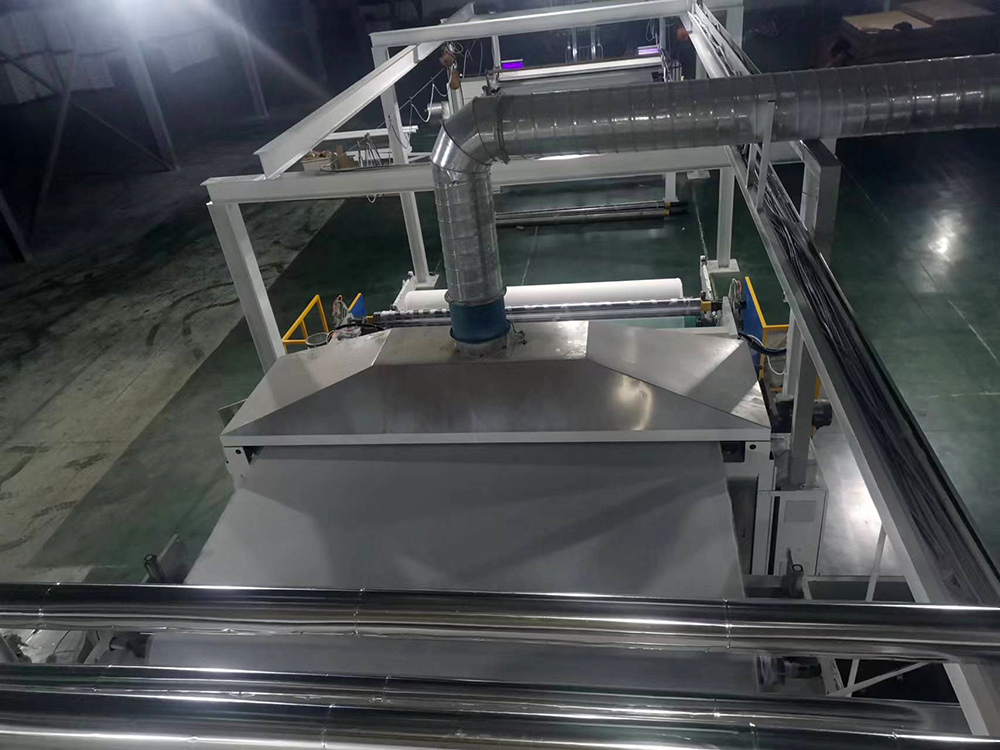

A máquina soprada por fusão consiste em vários componentes. Inclui uma extrusora, um dado, um soprador de ar quente, uma unidade formadora de teia, e um enrolador. A extrusora derrete o polímero e o extrusa através da matriz, que tem pequenos orifícios. O soprador de ar quente sopra ar quente nas fibras extrudadas, que esfriam e se unem para formar uma teia. A teia é então enrolada em um rolo pelo enrolador.

Nãotecidos fiados produzidos pela linha de produção

Primeiramente, o Linha de produção não abordada é usado para produzir tecidos não tecidos fiados. Os tecidos spunbonded são feitos por extrusão de filamentos de polímeros termoplásticos, como polipropileno, que são então resfriados e unidos para formar uma teia. Os tecidos spunbonded possuem alta resistência e durabilidade e são amplamente utilizados em diversas aplicações, como geotêxteis, agricultura, e mobiliário doméstico.

Em segundo lugar, a linha de produção de nãotecidos fiados consiste em vários componentes, incluindo uma extrusora, por spinneret, uma unidade de têmpera, uma unidade formadora de teia, e um enrolador. A extrusora derrete o polímero e o extrusa através da fieira, que tem vários furos. Os filamentos são então resfriados por ar frio e coletados em uma correia móvel, onde eles formam uma teia. A teia é então enrolada em um rolo pelo enrolador.

Máquina de tecido não tecido combinando diferentes fibras ou filamentos

O máquina de tecido não tecido é usado para produzir tecidos não tecidos combinando diferentes fibras ou filamentos por meio de mecânica, térmico, ou processos químicos. Os tecidos não tecidos produzidos por máquinas de tecido não tecido têm várias propriedades, dependendo das fibras e dos métodos de ligação utilizados. Tecidos não tecidos podem ser usados em diversas aplicações, como higiene, médico, automotivo, e filtração.

A máquina de tecido não tecido consiste em vários componentes. Inclui uma máquina de cardar, um remendo cruzado, um tear de agulha, e um enrolador. A cardadora separa e alinha as fibras ou filamentos, que são então dispostos em camadas pelo lapidador cruzado. As camadas são então unidas pelo tear de agulha, que usa agulhas farpadas para emaranhar as fibras ou filamentos. A teia colada é então enrolada em um rolo pela bobinadeira.